PRODUCTS

SCX Slime Control blocks slime growth for a fouling free boat bottom. SCX will dramatically increase your bottom paint performance, adding both durability and longevity to your hull coatings application.

Outdrives are built out of aluminum. This presents compatibility issues with antifouling that contain cuprous-oxide. That is why we developed Shelter Island Plus. It is safe to use on Aluminum. REMEMBER: Never apply an antifouling paint containing cuprous-oxide to aluminum.

Mega Gloss topside enamel technology has been the work horse product in the marine industry for approximately fifty years. Generally it dries reasonably fast, is easy to apply and has very good weathering characteristics. This technology is still used more than any other type.

Antifouling paints work by using biocides (chemicals) that slowly release during the season to repel underwater aquatic life.

APPLICATION

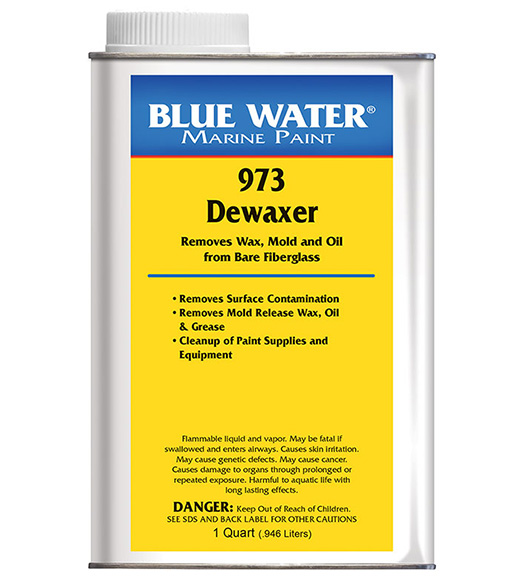

You must first bring metal to a uniform bright finish by sandblasting with nonferrous blast media such as clean silica sand or grind using coarse to medium emery cloth. Remove blast or sanding residue with broom and clear air hose. Then you use a solvent wash with Dewaxer and apply 4-5 coats of Bottom Protect Primer or Bottom Protect 70. Then you apply 2-3 coats of antifouling paint.

Clean hull properly, then wipe with Dewaxer to remove all surface contamination. Sand with 80 grit, wipe sanding with Dewaxer. Apply 3-5 coats of Bottom Protect Primer. Lastly, apply at least 2-3 coats minimum of antifouling paint.

You must first degrease and clean the surface with Dewaxer. Then you sand with 36-grit and then wipe with Dewaxer again. Apply at least 2 additional coats. Then apply 2-3 coats of Shelter Island Plus.

Blistering is caused by the permeability of fiberglass resin and the damage water can do by osmosis. Osmosis blistering, if left alone, will sooner or later destroy the integrity of your boat’s hull. Often times when a fiberglass boat is hauled, you’ll be able to see blisters on the bottom. You also repair the bottom when it blisters by applying Bottom Protect 8000.

You must lightly sand the surface and then use a good roller or brush. Thin when needed for proper flow and performance.

Most topside coating systems if constantly immersed or kept wet will tend to blister. Provided the boat is only put into the water for a few days then a topside coating can be used below the waterline.

Use 974 Thinner for cleaning equipment and paint brushes. You can also use Xylene, which is a product you can buy at your local hardware store.

Bottom paints are designed for overcoating after an overnight dry. Prior to launching, allow a minimum time to dry overnight. If drying conditions are poor, or if paint was applied too thickly, longer periods of drying will be required. Fresh coats of paint must be thoroughly dry before over coating.

Use the largest brush possible. Long flexible bristles are best for gloss paints. When applying by brush a good technique is the “Criss-Cross” method. First apply paint to the surface with diagonal brushing strokes from the left and right. This is then spread further with light vertical strokes. This results in brush marks being able to flow out to give the best possible finish.

Using a roller (a foam roller is best for this technique), roll some paint onto the boat hull, then “tip it out” by lightly dragging a dry hair bristle brush horizontally through it. Give the surface a couple of minutes to level out. If you see brush strokes, add a capful of thinner and test again. Stop adding thinner when the stroke marks disappear.